Risk assessments are the foundation of workplace safety. They help you identify what could cause harm, evaluate the likelihood and severity of that harm, and put controls in place to protect your workers. In this comprehensive guide, we'll walk you through everything you need to know about conducting effective risk assessments in 2026.

What is a Risk Assessment?

A risk assessment is a systematic process of identifying hazards in your workplace, evaluating the risks they pose, and determining appropriate control measures. It's not just a legal requirement—it's a practical tool that helps you protect your employees, contractors, visitors, and anyone else who might be affected by your work activities.

At its core, a risk assessment answers three fundamental questions:

- What could go wrong? (Hazard identification)

- How likely is it, and how bad could it be? (Risk evaluation)

- What are we doing about it? (Control measures)

A hazard is something with the potential to cause harm (e.g., a wet floor). A risk is the likelihood that harm will actually occur and how severe it might be (e.g., someone slipping and breaking their wrist).

Legal Requirements

In the UK, risk assessments are a legal requirement under the Management of Health and Safety at Work Regulations 1999. Every employer must:

- Conduct a suitable and sufficient assessment of risks to employees and others

- Record the significant findings if you have 5 or more employees

- Review and update assessments when circumstances change

- Implement the control measures identified

- Provide information and training to employees about the risks

The Health and Safety Executive (HSE) can inspect your risk assessments at any time, and failure to have adequate assessments in place can result in enforcement action, improvement notices, or prosecution.

The HSE has increased its focus on digital record-keeping and audit trails. Using safety management software like Safety Mate® helps demonstrate compliance and makes it easier to keep assessments up to date.

The 5 Steps of Risk Assessment

The HSE recommends a straightforward 5-step approach to risk assessment:

-

Identify the hazards

Walk around your workplace, talk to employees, review incident records, and think about what activities could cause harm.

-

Decide who might be harmed and how

Consider employees, contractors, visitors, members of the public, and vulnerable groups like young workers or pregnant women.

-

Evaluate the risks and decide on precautions

For each hazard, consider how likely harm is and how severe it could be. Then identify what controls are already in place and what more you could do.

-

Record your findings and implement them

Write down what you found and the actions you're taking. Make sure the controls are actually put in place.

-

Review and update regularly

Risk assessments aren't one-and-done. Review them when things change, after incidents, or at least annually.

Let's look at how to apply each of these steps using Safety Mate®.

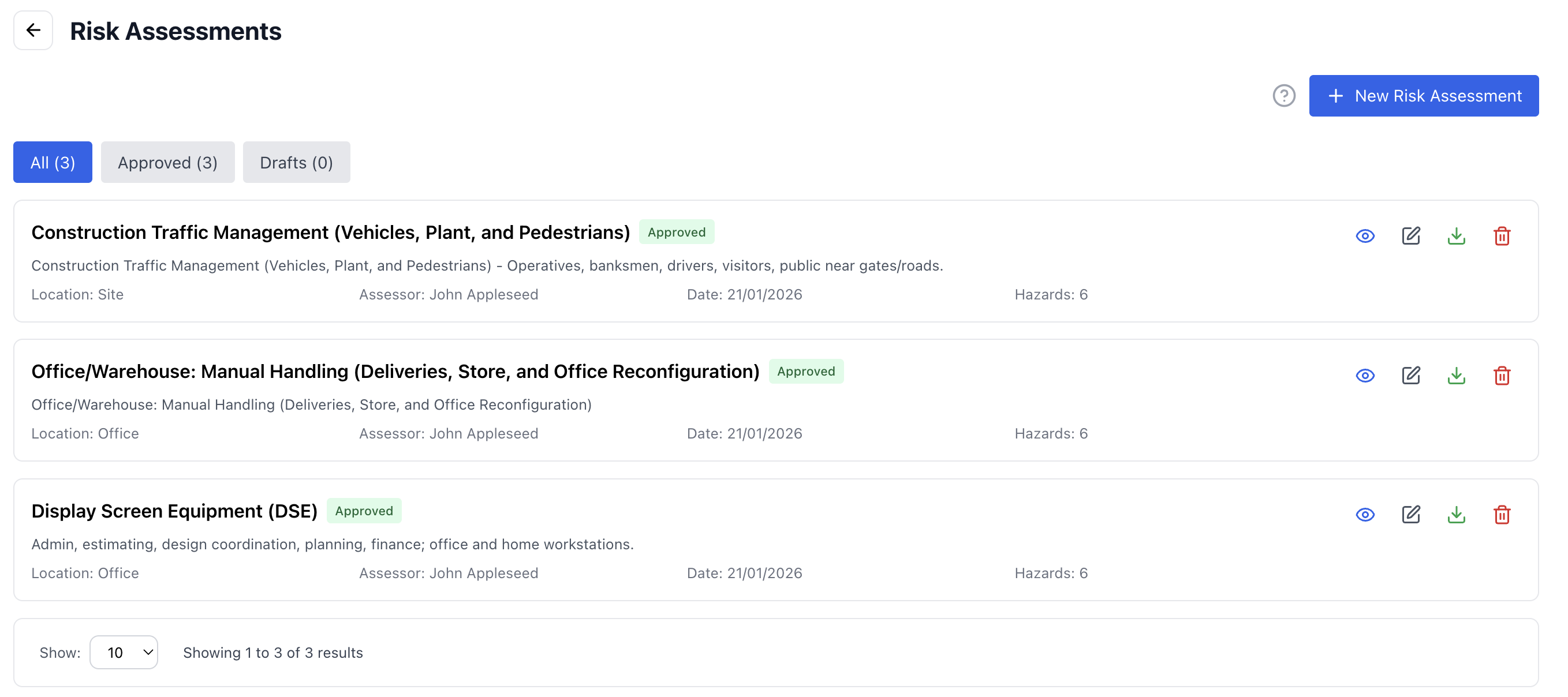

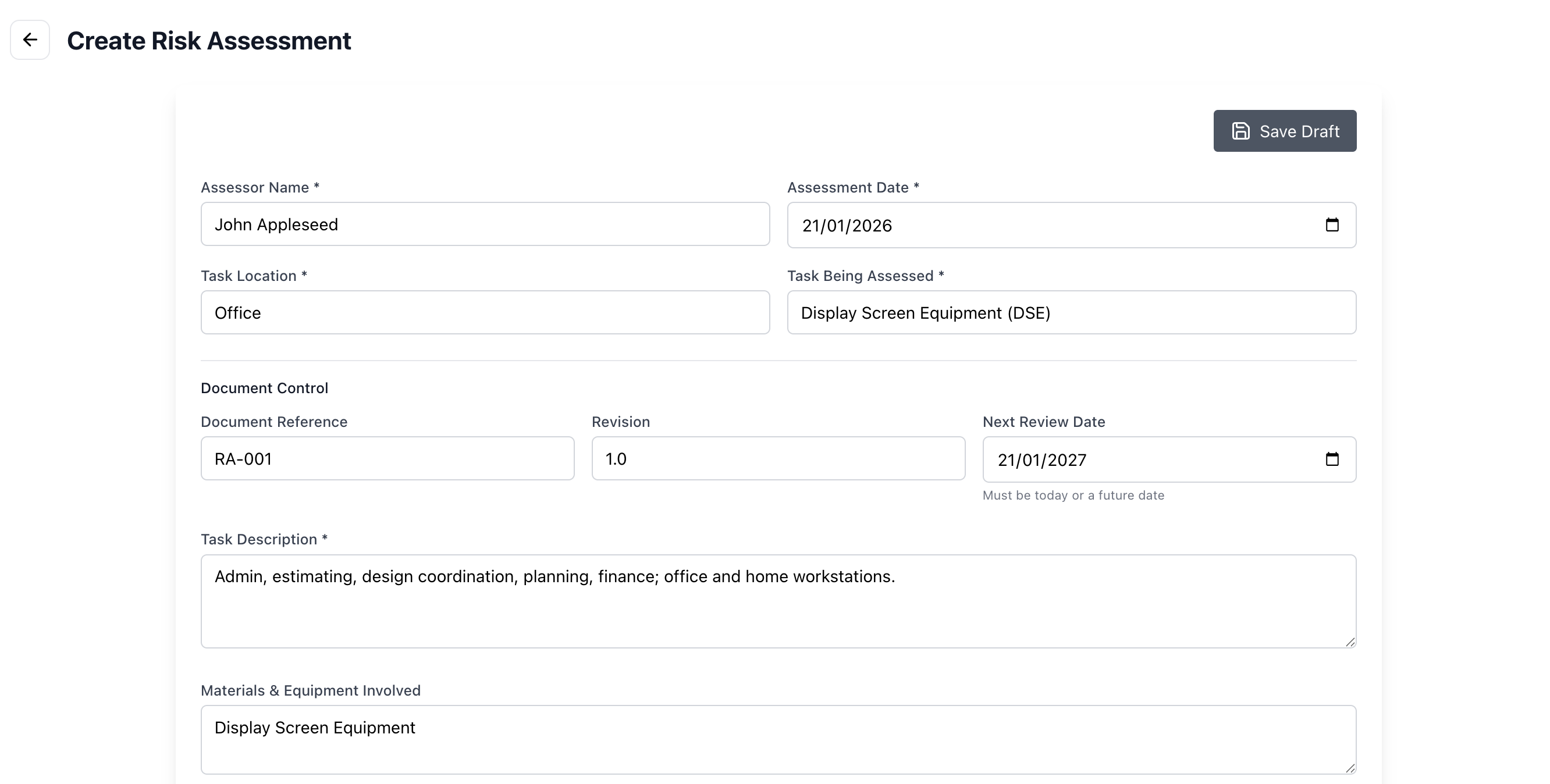

Getting Started in Safety Mate®

Safety Mate® makes risk assessments straightforward. Here's how to create a new risk assessment:

- Navigate to Risk Management in the sidebar

- Click the "New Risk Assessment" button

- Enter a clear, descriptive title

- Add context in the description field

- Link it to a project if applicable

Use clear, specific titles like "Manual Handling - Warehouse Operations" rather than vague ones like "Warehouse Risk Assessment". This makes it easier to find and manage assessments later.

Step 1: Identify Hazards

The first step is to identify everything in your workplace that could potentially cause harm. Think about:

Physical Hazards

- Slips, trips and falls

- Moving machinery

- Working at height

- Manual handling

- Vehicles and traffic

- Noise and vibration

Health Hazards

- Hazardous substances

- Dust and fumes

- Biological agents

- Radiation

- Extreme temperatures

- Poor ergonomics

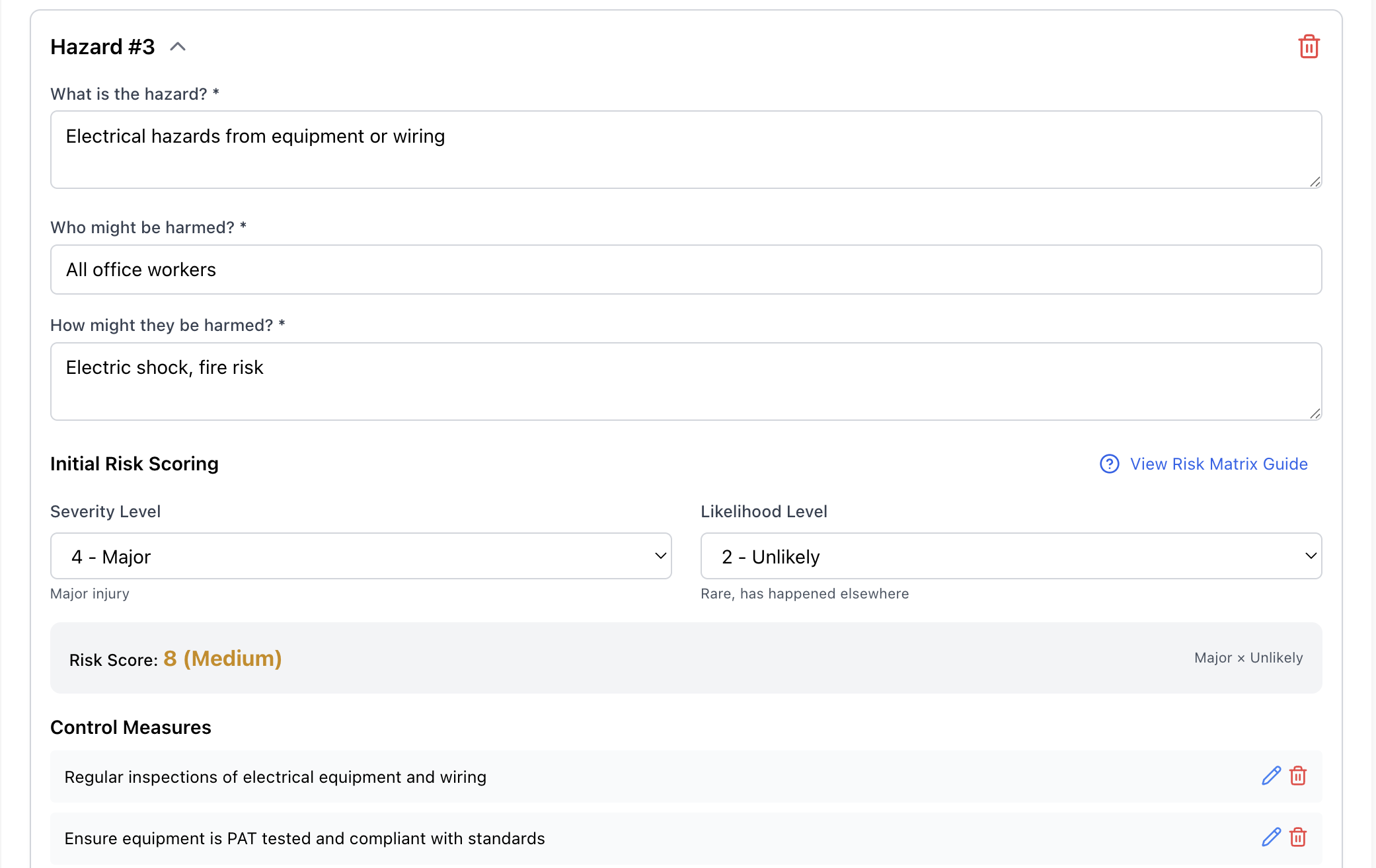

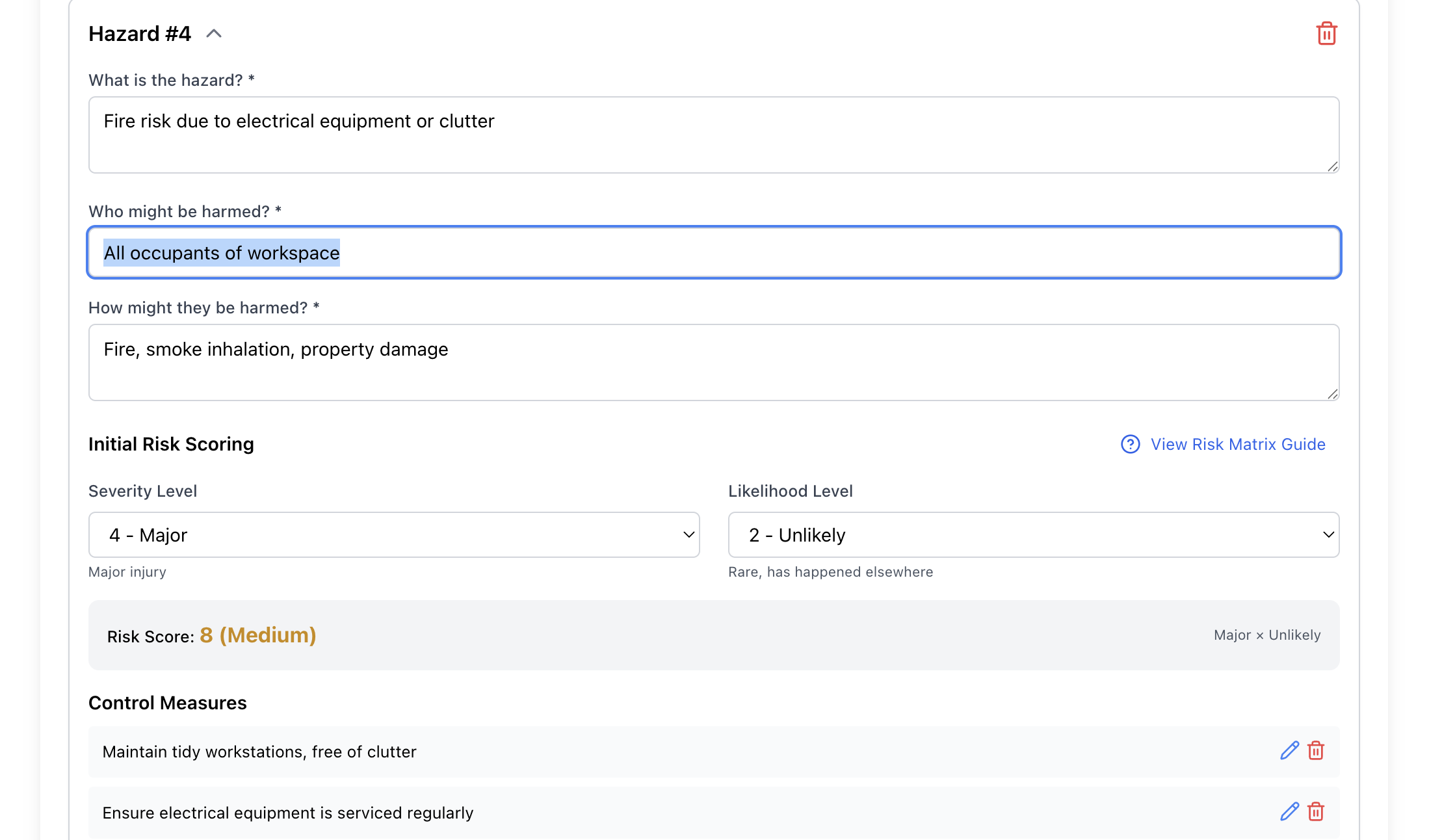

In Safety Mate®, you add hazards to your risk assessment by clicking "Add Hazard". For each hazard, describe:

- What the hazard is

- Where it's found

- What activities involve the hazard

Step 2: Who Might Be Harmed

For each hazard, think about who could be affected:

- Employees - full-time, part-time, temporary

- Contractors - working on your site

- Visitors - clients, delivery drivers, inspectors

- Members of the public - if your work affects them

- Vulnerable groups - young workers, pregnant women, people with disabilities, lone workers

Safety Mate® lets you specify who is at risk for each hazard, which helps ensure your control measures are appropriate for everyone affected.

Step 3: Evaluate the Risks

Now you need to evaluate each risk by considering two factors:

- Likelihood - How likely is it that the hazard will cause harm?

- Severity - If harm does occur, how bad could it be?

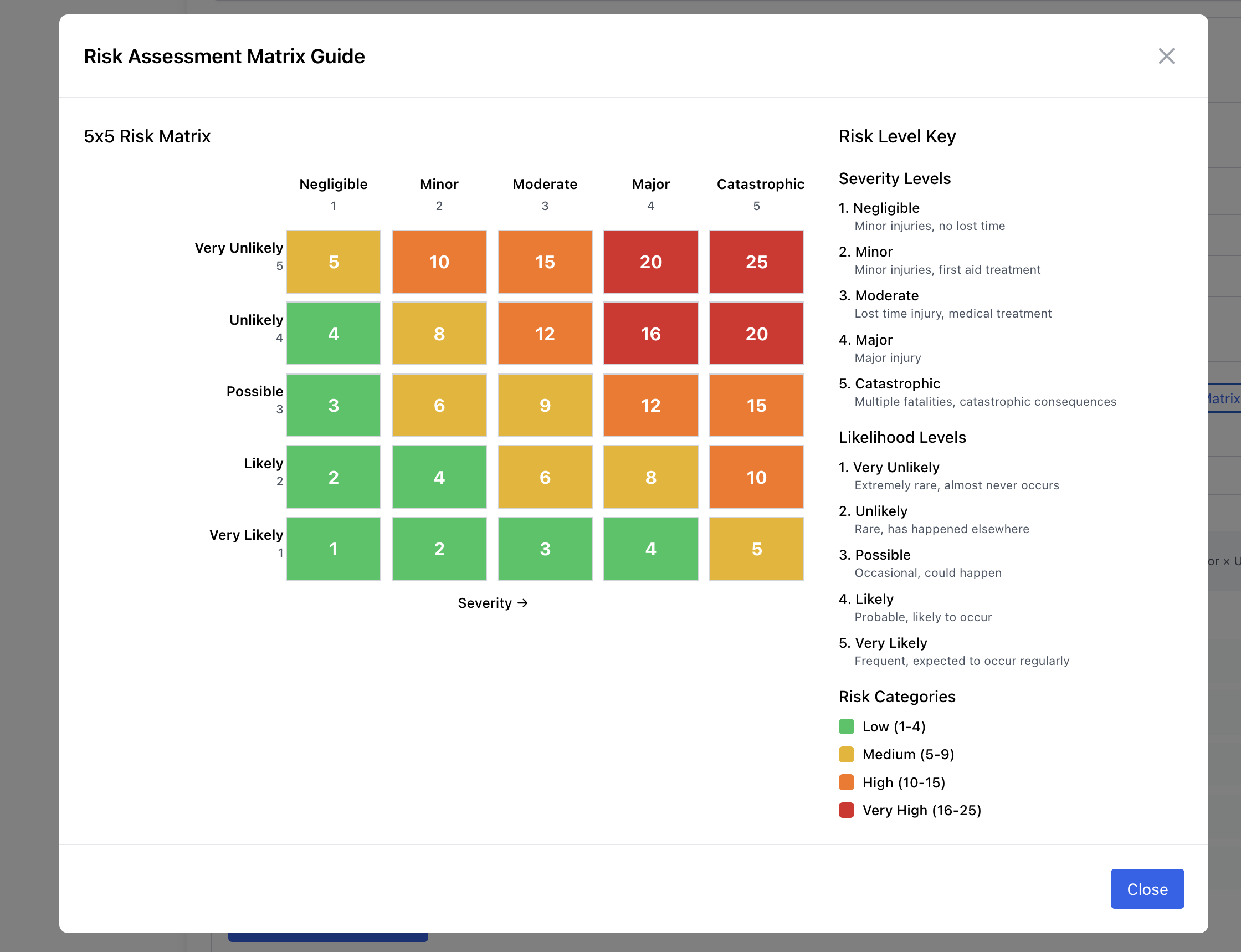

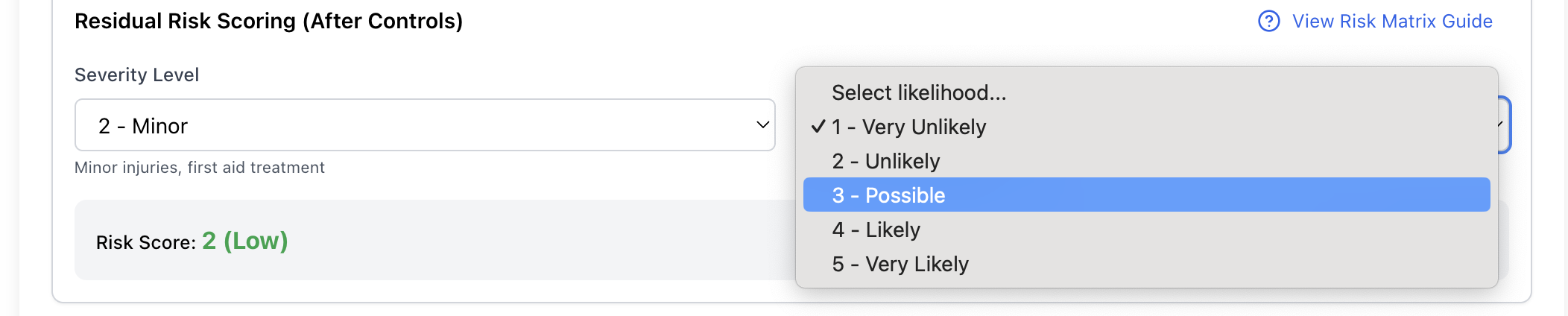

Safety Mate® uses a 5x5 risk matrix to calculate risk ratings:

Likelihood Scale

| Rating | Description | Frequency |

|---|---|---|

| 1 - Very Unlikely | Could happen but very rare | Less than once in 10 years |

| 2 - Unlikely | Not expected but possible | Once in 5-10 years |

| 3 - Possible | Could occur sometime | Once in 1-5 years |

| 4 - Likely | Will probably happen | Once per year |

| 5 - Very Likely | Expected to happen frequently | Multiple times per year |

Severity Scale

| Rating | Injury/Health | Example |

|---|---|---|

| 1 - Negligible | No injury or very minor | Small bruise, minor discomfort |

| 2 - Minor | First aid required | Minor cuts, sprains |

| 3 - Moderate | Medical treatment needed | Fractures, burns, hearing loss |

| 4 - Major | Serious injury/illness | Amputation, major fracture, cancer |

| 5 - Catastrophic | Death or permanent disability | Fatality, paralysis |

The risk score is calculated by multiplying likelihood × severity. This gives you a score from 1-25, which is categorised as:

Step 4: Record Control Measures

Control measures are the actions you take to eliminate or reduce risks. When deciding on controls, follow the hierarchy of controls:

Elimination

Remove the hazard completely. This is the most effective control.

Example: Stop using a hazardous chemical by finding an alternative processSubstitution

Replace the hazard with something less dangerous.

Example: Use a less toxic cleaning productEngineering Controls

Isolate people from the hazard through physical means.

Example: Install machine guards, ventilation systems, barriersAdministrative Controls

Change the way people work through procedures and training.

Example: Safe work procedures, training, signage, job rotationPPE (Last Resort)

Personal protective equipment as the final layer of protection.

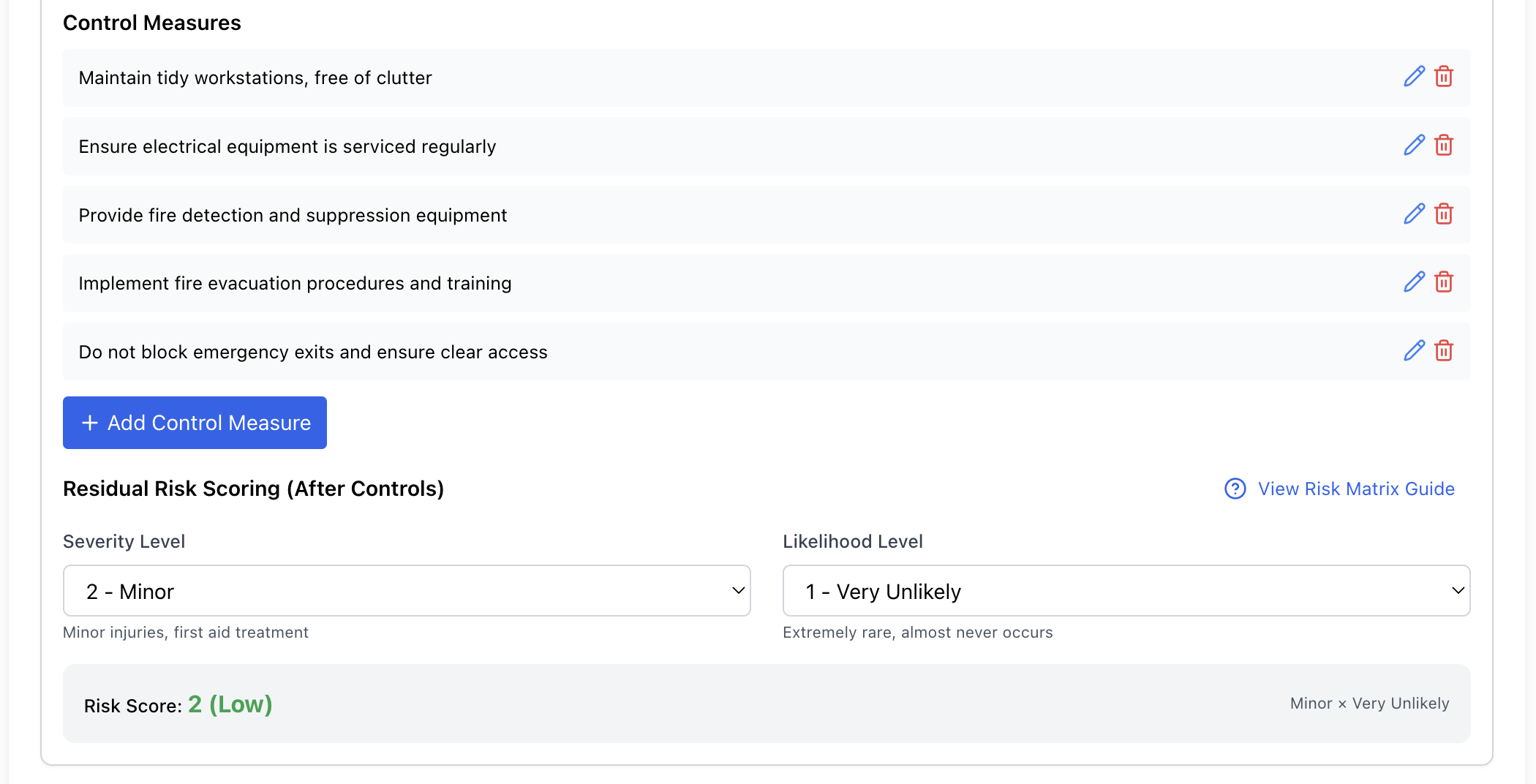

Example: Safety glasses, gloves, hearing protection, respiratorsIn Safety Mate®, you add control measures to each hazard and specify whether they're existing controls or new actions required:

Residual Risk

After implementing controls, you should reassess the risk to determine the residual risk - the level of risk that remains. Ideally, your controls should reduce the risk to an acceptable level.

Safety Mate® lets you create tasks directly from your risk assessment. Assign control measures to team members with due dates to ensure they're implemented.

Step 5: Review and Update

Risk assessments must be living documents. Review and update them:

- When there are significant changes to the work activity

- After an incident, accident, or near miss

- When new equipment or substances are introduced

- When legislation or guidance changes

- At regular intervals (at least annually)

Safety Mate® makes it easy to track when assessments were last reviewed and set reminders for regular reviews:

Common Mistakes to Avoid

Being too generic

Avoid copy-pasting generic assessments. They should be specific to your workplace and activities.

Not involving workers

The people doing the work often know the hazards best. Involve them in the assessment process.

Overcomplicating it

Risk assessment doesn't need to be complicated. Focus on significant risks, not every trivial hazard.

Filing and forgetting

A risk assessment gathering dust is worthless. Communicate findings and review regularly.

Not following through

Identifying controls is pointless if you don't implement them. Assign responsibility and track completion.

Communicating Risk Assessments

A risk assessment is only effective if the people who need to follow it actually understand it. Safety Mate® includes powerful features to ensure your risk assessments reach everyone and are clearly understood.

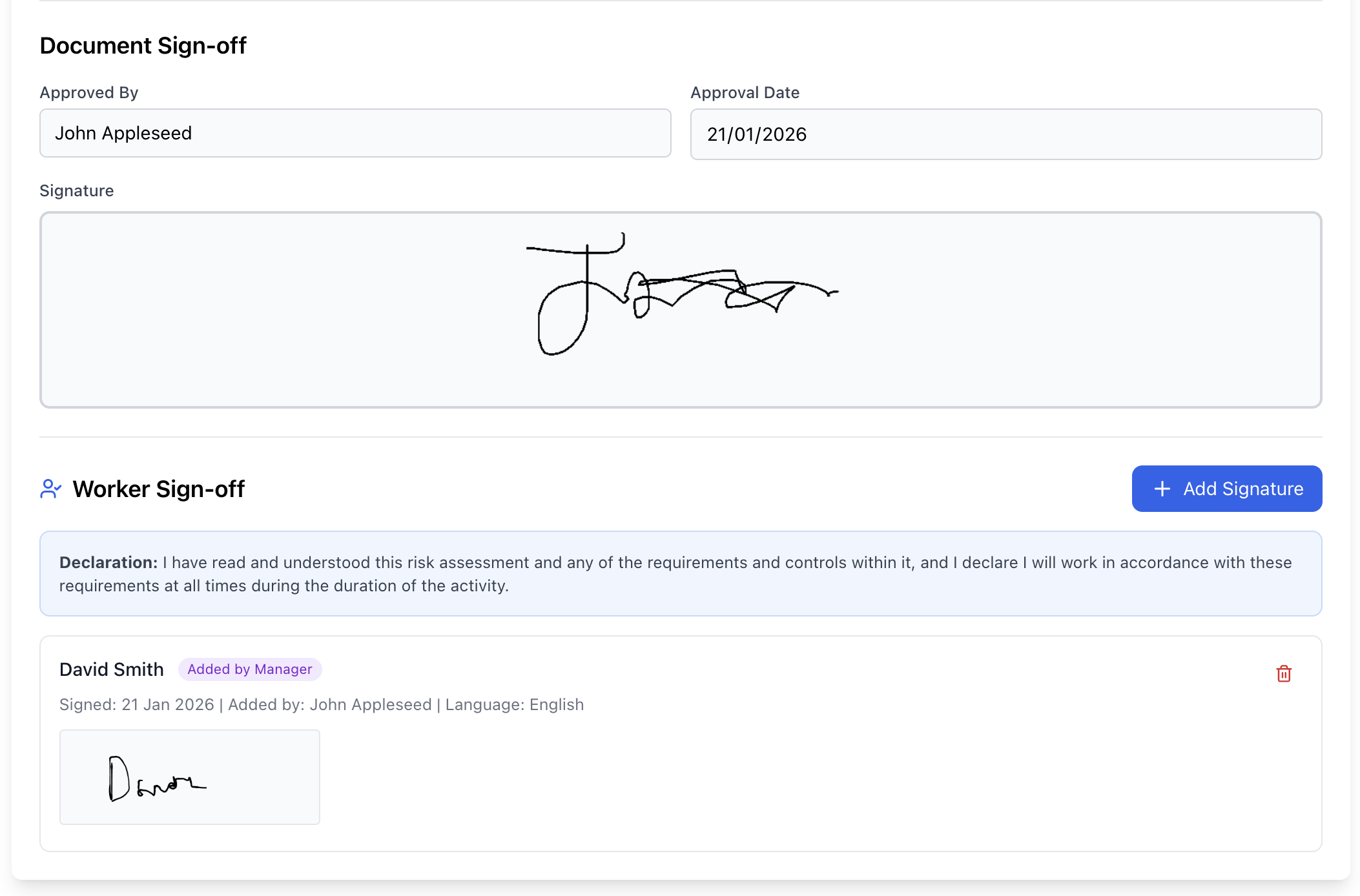

Digital Signatures for Acknowledgement

Getting workers to acknowledge they've read and understood a risk assessment is crucial for compliance and accountability. Safety Mate® allows you to:

- Send risk assessments directly to team members' devices

- Capture digital signatures as proof of understanding

- Track who has and hasn't acknowledged each assessment

- Set automatic reminders for outstanding acknowledgements

- Generate audit-ready reports of all signatures

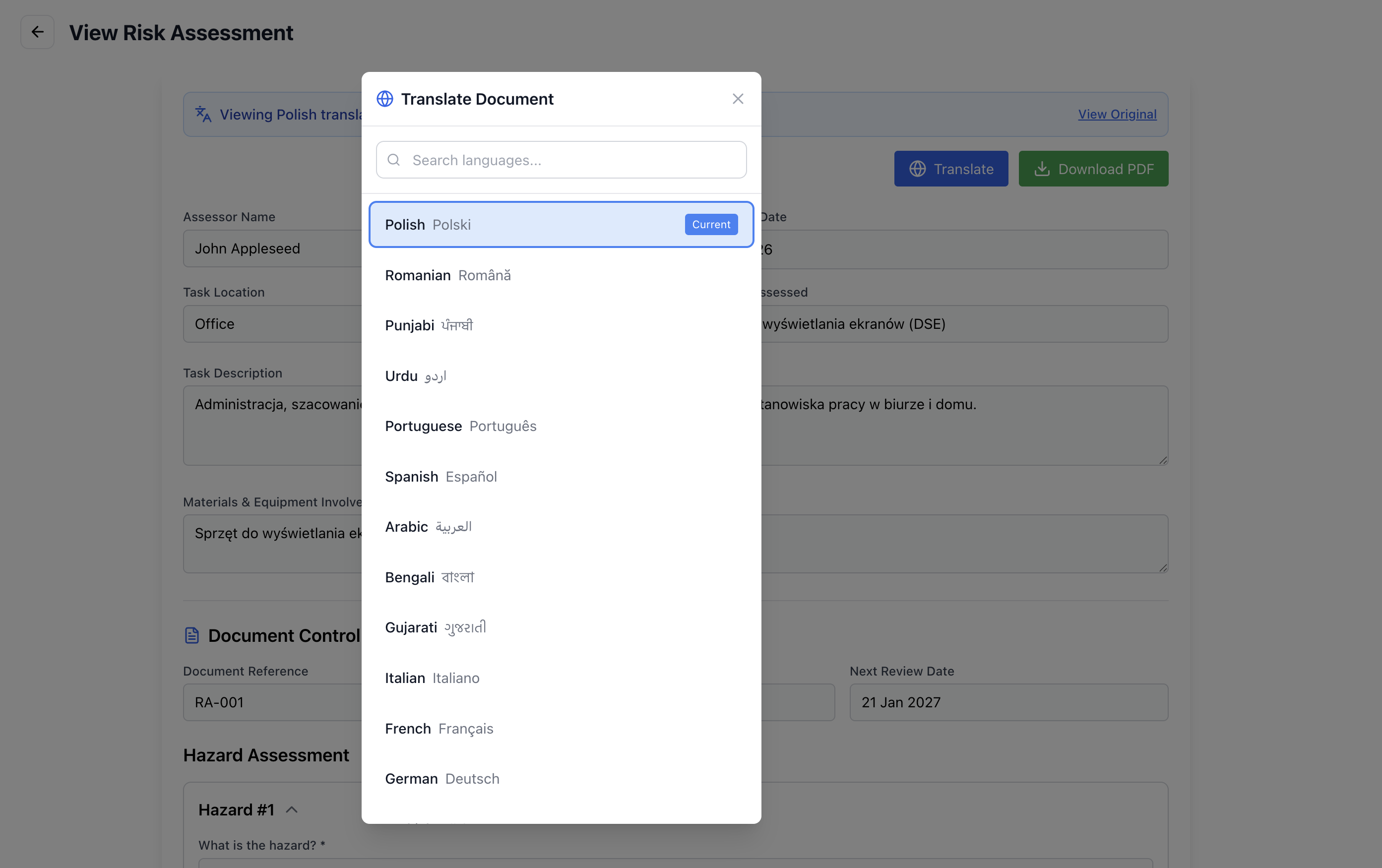

Multi-Language Translation

In diverse workplaces, language barriers can be a significant safety risk. If workers can't read or understand a risk assessment, they can't follow it. Safety Mate® solves this with automatic translation to over 20 languages:

European Languages

- Polish

- Romanian

- Portuguese

- Spanish

- French

- German

Asian & Other Languages

- Hindi

- Urdu

- Arabic

- Mandarin

- Bengali

- And many more...

Providing risk assessments in workers' native languages isn't just good practice—it demonstrates your commitment to inclusive safety and can significantly reduce incidents caused by misunderstanding.

Conclusion

Risk assessments are a cornerstone of good safety management. They help you identify hazards before they cause harm, demonstrate legal compliance, and create a safer workplace for everyone.

By following the 5-step process and using tools like Safety Mate® to manage your assessments, you can:

- Create thorough, well-documented risk assessments

- Keep track of control measures and who's responsible

- Set reminders for regular reviews

- Demonstrate compliance to auditors and inspectors

- Build a culture where safety is everyone's responsibility

Ready to simplify your risk assessments?

Safety Mate® makes it easy to create, manage and review risk assessments. Start your free 7-day trial today.

Start free trial