ISO 45001 is the international standard for occupational health and safety (OH&S) management systems. Whether you're pursuing formal certification or simply want to implement best practices, this guide walks you through everything you need to know to build an effective OH&S management system.

What is ISO 45001?

ISO 45001:2018 is the first truly global international standard for occupational health and safety. Published in March 2018, it replaced OHSAS 18001 and provides a framework for organisations to proactively improve their OH&S performance by:

- Preventing work-related injury and ill health

- Providing safe and healthy workplaces

- Eliminating hazards and minimising OH&S risks

- Continually improving the OH&S management system

The standard follows the same high-level structure (HLS) as other ISO management system standards like ISO 9001 (Quality) and ISO 14001 (Environmental), making it easier to integrate multiple management systems.

OHSAS 18001 was withdrawn in March 2021. If your organisation was certified to OHSAS 18001, you should have already migrated to ISO 45001. The good news is that ISO 45001 builds on many of the same principles.

Benefits of ISO 45001 Certification

Implementing ISO 45001 delivers both tangible and intangible benefits:

Reduced Incidents

Systematic hazard identification and risk control leads to fewer workplace injuries and illnesses.

Cost Savings

Lower insurance premiums, reduced compensation claims, and less downtime from incidents.

Legal Compliance

Structured approach to identifying and meeting legal requirements reduces compliance risk.

Worker Engagement

Emphasis on consultation and participation improves morale and safety culture.

Competitive Advantage

Certification demonstrates commitment to safety, often required for tenders and contracts.

Continual Improvement

Built-in mechanisms ensure your OH&S performance keeps getting better over time.

Structure of the Standard

ISO 45001 follows the Plan-Do-Check-Act (PDCA) cycle and is organised into 10 clauses. Clauses 1-3 are introductory, while clauses 4-10 contain the requirements:

Context of the Organisation

Understanding your organisation, stakeholders, and defining the scope of your OH&S management system.

Leadership and Worker Participation

Top management commitment, OH&S policy, roles and responsibilities, and worker consultation.

Planning

Addressing risks and opportunities, hazard identification, legal requirements, and OH&S objectives.

Support

Resources, competence, awareness, communication, and documented information.

Operation

Operational planning and control, emergency preparedness and response.

Performance Evaluation

Monitoring, measurement, analysis, internal audit, and management review.

Improvement

Incident investigation, nonconformity, corrective action, and continual improvement.

Clause 4: Context of the Organisation

Before building your management system, you need to understand the context in which it operates:

4.1 Understanding the Organisation

Identify internal and external issues that affect your ability to achieve OH&S objectives:

- External: Economic conditions, industry trends, regulatory environment, technology changes

- Internal: Culture, structure, capabilities, existing systems and processes

4.2 Understanding Stakeholder Needs

Identify interested parties and their relevant requirements:

| Interested Party | Example Requirements |

|---|---|

| Workers | Safe working conditions, consultation on safety matters, training |

| Regulators | Compliance with health and safety legislation |

| Customers | Safe products/services, contractor safety requirements |

| Insurers | Risk management, incident reporting, safety standards |

| Contractors | Clear safety requirements, coordination, site inductions |

4.3 & 4.4 Scope and Management System

Define the boundaries of your OH&S management system, considering:

- Physical locations and activities covered

- Products, services, and processes included

- Any exclusions (must be justified)

Start with a manageable scope—you can always expand later. It's better to have a well-implemented system covering part of your organisation than a poorly implemented one trying to cover everything.

Clause 5: Leadership & Worker Participation

ISO 45001 places strong emphasis on leadership commitment and worker involvement—more so than its predecessor OHSAS 18001.

5.1 Leadership and Commitment

Top management must demonstrate leadership by:

- Taking overall responsibility and accountability for OH&S

- Ensuring the OH&S policy and objectives are established and compatible with strategic direction

- Ensuring integration of OH&S requirements into business processes

- Ensuring resources are available

- Promoting continual improvement

- Supporting other relevant management roles

5.2 OH&S Policy

Your OH&S policy must include commitments to:

- Provide safe and healthy working conditions

- Eliminate hazards and reduce OH&S risks

- Comply with legal and other requirements

- Consult and participate with workers

- Continually improve the OH&S management system

5.4 Worker Participation and Consultation

A key difference from OHSAS 18001 is the emphasis on worker participation:

Consultation

Seeking views before making decisions about:

- Stakeholder needs and expectations

- OH&S policy and objectives

- Roles and responsibilities

- How to meet legal requirements

- Audit programmes and criteria

Participation

Involving workers in decisions about:

- Mechanisms for consultation

- Hazard identification and risk assessment

- Actions to control risks

- Competence and training needs

- Incident investigation

Clause 6: Planning

Planning is at the heart of the PDCA cycle. ISO 45001 requires a proactive, risk-based approach.

6.1.2 Hazard Identification and Risk Assessment

Establish processes to identify hazards and assess risks on an ongoing basis, considering:

- How work is organised and social factors

- Routine and non-routine activities

- Past incidents (internal and external)

- Potential emergency situations

- People—including contractors, visitors, and vulnerable groups

- Changes to processes, equipment, or knowledge

6.1.3 Legal and Other Requirements

Maintain a process to identify, access, and evaluate compliance with:

- Health and safety legislation

- Regulations and codes of practice

- Collective agreements

- Voluntary commitments

6.2 OH&S Objectives and Planning

Set measurable objectives that are:

- Consistent with your OH&S policy

- Measurable (or capable of performance evaluation)

- Monitored and communicated

- Updated as appropriate

Don't just measure incident rates. Include leading indicators like training completion, hazard reports, audit scores, and near-miss reporting rates. These help predict and prevent incidents rather than just counting them after they happen.

Clause 7: Support

The support clause covers the resources and enablers needed to implement and maintain your OH&S management system.

7.1 Resources

Determine and provide the resources needed, including:

- People with appropriate competencies

- Infrastructure (equipment, facilities)

- Budget and time

- Technology and systems

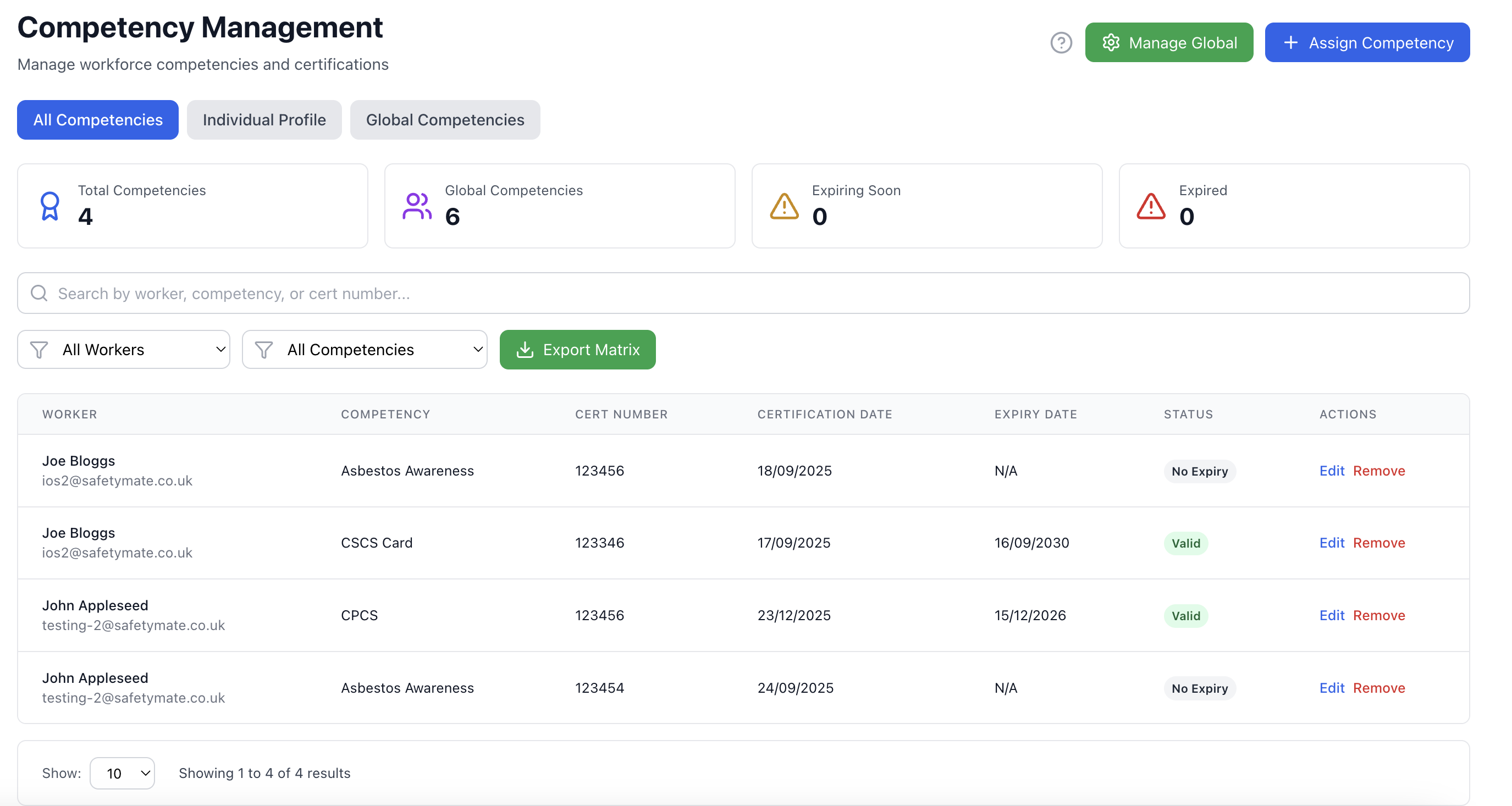

7.2 Competence

Ensure workers are competent based on appropriate education, training, or experience. This includes:

- Determining competence requirements for roles affecting OH&S

- Providing training or taking other actions to achieve competence

- Evaluating the effectiveness of actions taken

- Retaining documented information as evidence

7.4 Communication

Establish processes for internal and external communications, determining:

- What to communicate

- When to communicate

- With whom to communicate

- How to communicate

7.5 Documented Information

Maintain documented information required by the standard and determined necessary for effectiveness. Key documents typically include:

- OH&S policy and objectives

- Scope of the management system

- Risk assessments and risk registers

- Legal register

- Training records

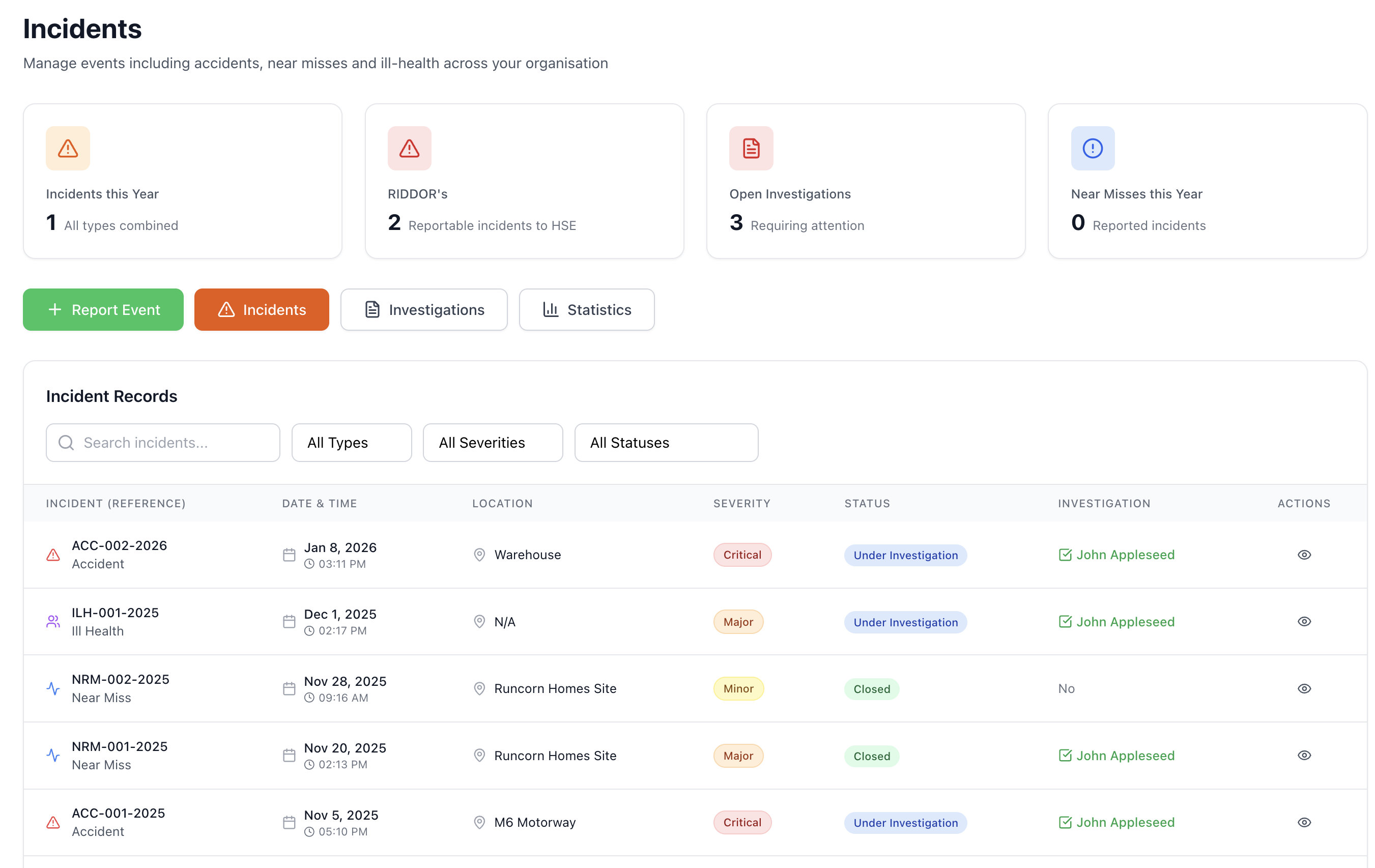

- Incident records and investigations

- Audit reports and management review minutes

Clause 8: Operation

The operation clause is about putting your plans into action—implementing the controls identified during planning.

8.1 Operational Planning and Control

Implement controls using the hierarchy of controls:

Elimination

Remove the hazard entirely

Example: Automate a dangerous manual processSubstitution

Replace with something less hazardous

Example: Use water-based paint instead of solvent-basedEngineering Controls

Isolate people from the hazard

Example: Install machine guards or ventilationAdministrative Controls

Change the way people work

Example: Procedures, training, job rotationPPE

Personal protective equipment as last resort

Example: Safety glasses, gloves, hearing protection8.1.4 Procurement and Contractors

Control processes for:

- Procurement of products and services

- Contractors and outsourced processes

- Ensuring OH&S requirements are met

8.2 Emergency Preparedness and Response

Establish processes to prepare for and respond to potential emergency situations:

- Identify potential emergencies

- Plan responses including first aid

- Provide training and drills

- Periodically test and review plans

- Communicate relevant information to workers

Clause 9: Performance Evaluation

You need to check that your management system is working effectively.

9.1 Monitoring, Measurement, Analysis and Evaluation

Determine what needs to be monitored and measured:

- Extent to which legal requirements are fulfilled

- Activities and operations related to identified hazards and risks

- Progress towards OH&S objectives

- Effectiveness of controls

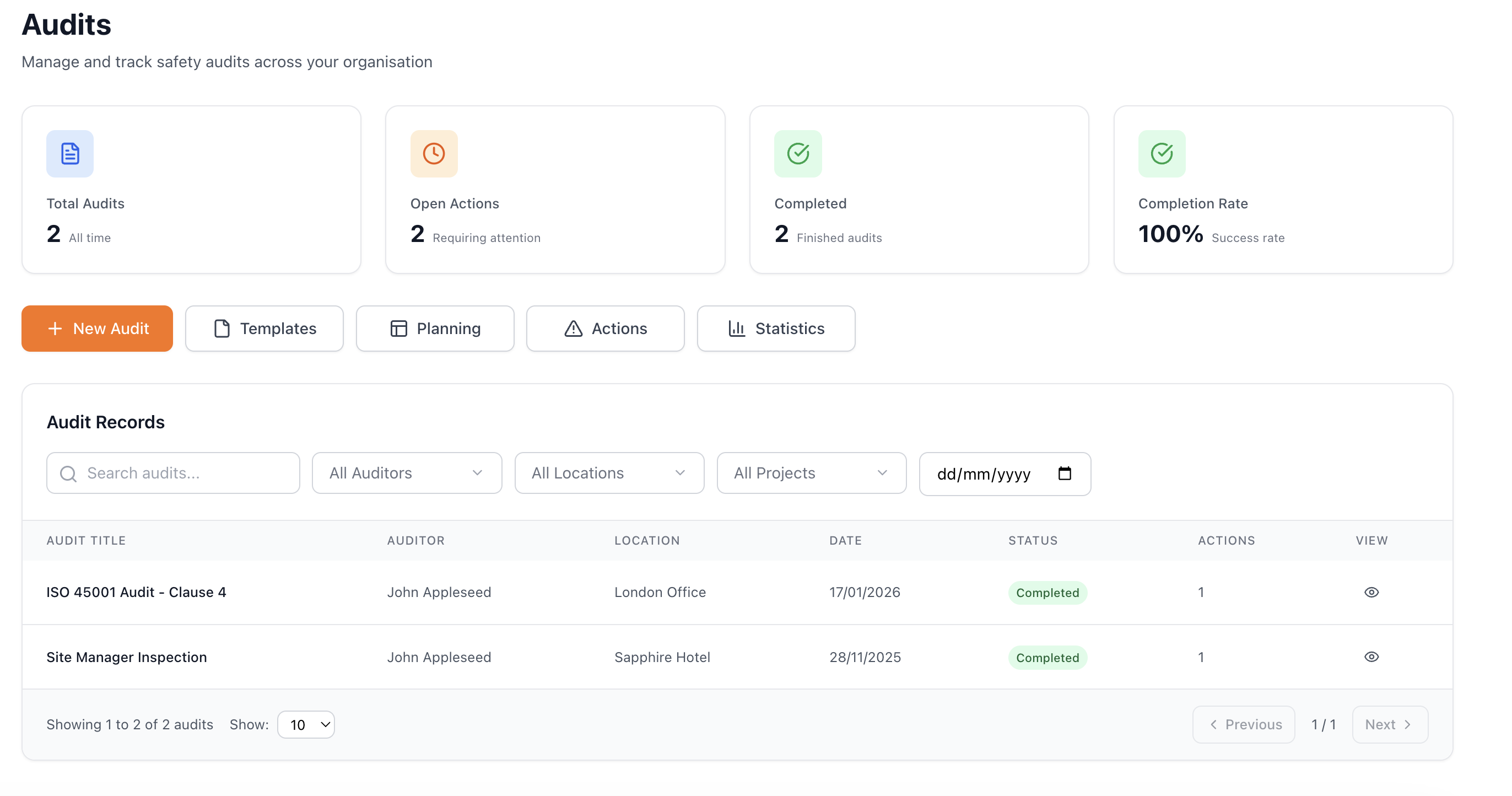

9.2 Internal Audit

Conduct internal audits at planned intervals to verify your system:

- Conforms to ISO 45001 requirements

- Conforms to your own requirements

- Is effectively implemented and maintained

9.3 Management Review

Top management must review the OH&S management system at planned intervals. Review inputs include:

- Status of actions from previous reviews

- Changes in external and internal issues

- OH&S performance (incidents, nonconformities, monitoring results, audit results)

- Adequacy of resources

- Relevant communications from interested parties

- Opportunities for continual improvement

Clause 10: Improvement

The final clause closes the PDCA loop by addressing how to improve your OH&S management system.

10.2 Incident, Nonconformity and Corrective Action

When incidents or nonconformities occur:

- React to control and correct it

- Evaluate the need for corrective action by investigating

- Determine root causes

- Determine if similar issues exist or could occur

- Implement corrective action needed

- Review effectiveness of corrective action

- Make changes to the OH&S management system if needed

10.3 Continual Improvement

Continually improve the suitability, adequacy and effectiveness of the OH&S management system by:

- Enhancing OH&S performance

- Promoting a culture that supports the system

- Promoting worker participation

- Communicating relevant results to workers

- Maintaining and retaining documented information

Implementation Steps

Here's a practical roadmap for implementing ISO 45001:

Preparation

- Secure top management commitment and resources

- Appoint an implementation team/project manager

- Purchase and study the ISO 45001 standard

- Consider training for key personnel

- Conduct a gap analysis against current practices

Planning

- Define the scope of your management system

- Identify context, interested parties, and their requirements

- Conduct comprehensive hazard identification and risk assessment

- Identify legal and other requirements

- Establish OH&S policy and objectives

Implementation

- Develop and document required procedures

- Implement operational controls

- Establish communication processes

- Deliver training and awareness programmes

- Set up document control systems

Checking

- Implement monitoring and measurement

- Conduct internal audits

- Hold management reviews

- Address nonconformities and implement corrective actions

- Review and improve

Certification (Optional)

- Select an accredited certification body

- Undergo Stage 1 audit (documentation review)

- Address any findings

- Undergo Stage 2 audit (implementation verification)

- Maintain certification through surveillance audits

Common Implementation Challenges

Lack of Top Management Commitment

ISO 45001 specifically requires top management leadership. Without genuine commitment, implementation becomes a paper exercise. Solution: Present the business case, involve leaders in audits, and make OH&S a standing agenda item.

Over-Documentation

Creating excessive procedures that nobody reads or follows. ISO 45001 is less prescriptive about documentation than OHSAS 18001. Solution: Document what adds value and is actually used.

Poor Worker Engagement

Treating workers as subjects rather than participants. Solution: Involve workers from the start, create genuine consultation mechanisms, and act on their input.

Focusing on Certification Over Improvement

Treating certification as the end goal rather than a milestone. Solution: Focus on genuine OH&S improvement; certification will follow.

Resource Constraints

Underestimating the time and effort required. Solution: Be realistic about resources, phase implementation if needed, and use technology to streamline processes.

Conclusion

Implementing ISO 45001 is a significant undertaking, but the benefits—reduced incidents, improved compliance, better worker engagement, and competitive advantage—make it worthwhile. The key is to focus on genuine OH&S improvement rather than just meeting requirements on paper.

Key takeaways:

- ISO 45001 provides a framework for proactive OH&S management

- Leadership commitment and worker participation are essential

- Focus on risk-based thinking and the hierarchy of controls

- Document what adds value, not just what's required

- Use technology to streamline implementation and maintenance

- Aim for continual improvement, not just certification

Ready to implement ISO 45001?

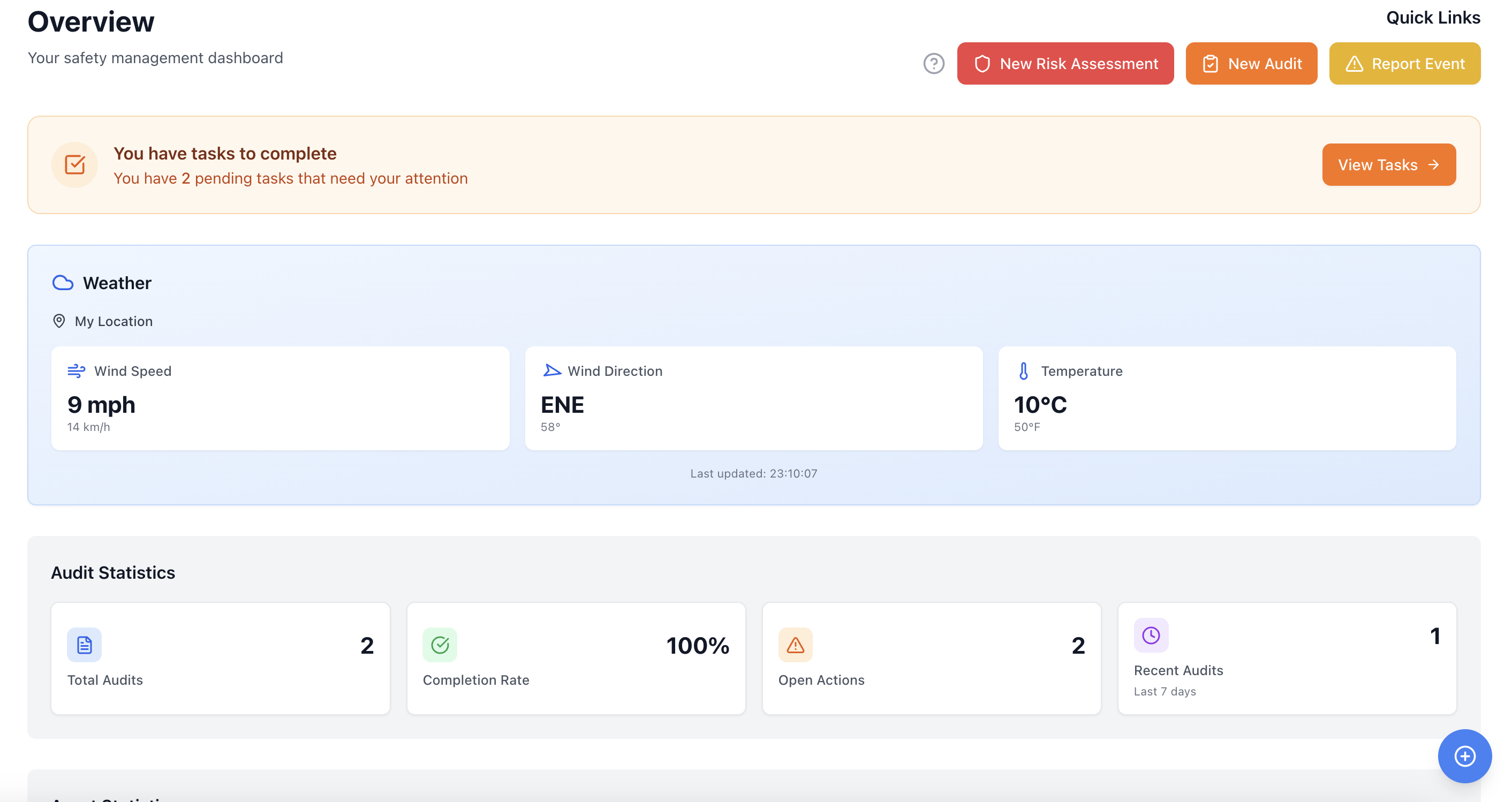

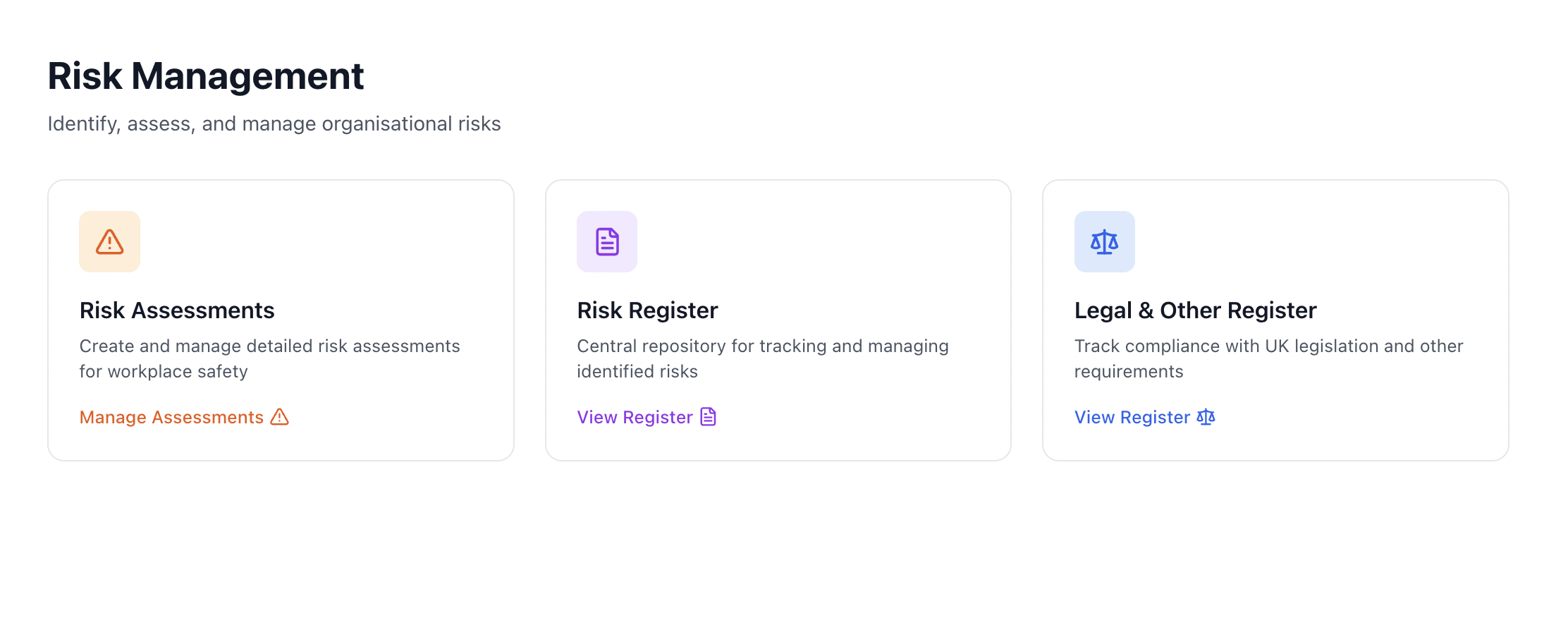

Safety Mate® provides the tools you need to implement and maintain an ISO 45001-compliant OH&S management system—from risk assessments to audits to incident management.

Start free trial