Safety audits are one of the most powerful tools for identifying hazards, verifying compliance, and driving continuous improvement in workplace safety. When done well, they go beyond ticking boxes—they create real change. This guide walks you through how to plan, conduct, and follow up on safety audits that actually make a difference.

What is a Safety Audit?

A safety audit is a systematic, independent examination of your workplace to assess how well your health and safety management system is working. Unlike a simple inspection (which focuses on conditions at a moment in time), an audit looks at the bigger picture: policies, procedures, training, documentation, and whether they're being followed in practice.

A good safety audit answers questions like:

- Are our safety policies and procedures adequate?

- Are employees following the procedures we've put in place?

- Is our training effective?

- Are we meeting our legal obligations?

- What can we do better?

An inspection checks physical conditions (Is the fire exit clear? Is PPE being worn?). An audit evaluates systems and processes (Do we have a fire evacuation procedure? Is it documented? Are people trained on it?).

Why Audits Matter

Regular safety audits deliver significant benefits for your organisation:

Legal Compliance

Demonstrate you're meeting your duties under health and safety law and avoid enforcement action.

Identify Hazards

Find problems before they cause incidents—including issues that day-to-day familiarity can hide.

Continuous Improvement

Track progress over time and build a culture where safety standards continuously rise.

Engage Workers

Involve employees in the audit process and demonstrate that their safety matters.

Types of Safety Audits

Different types of audits serve different purposes. You'll likely use a combination:

Internal Audits

Conducted by your own staff (ideally someone independent of the area being audited). These are your regular health checks—frequent, practical, and focused on continuous improvement.

External Audits

Conducted by third parties such as certification bodies, consultants, or regulatory inspectors. These provide independent verification and are often required for certifications like ISO 45001.

Compliance Audits

Focused specifically on legal requirements—are you meeting your duties under HSWA, RIDDOR, COSHH, and other regulations?

Behavioural Audits

Observe how people actually work, not just what procedures say. These help identify gaps between written procedures and real-world practice.

The most effective audit programmes combine different types. Use frequent internal audits to maintain standards, with periodic external audits to get fresh perspectives.

Planning Your Audit

Good planning is the foundation of an effective audit. Before you start, you need to be clear on scope, criteria, and logistics.

1. Define the Scope

What are you auditing? This could be:

- A specific location (warehouse, construction site, office)

- A particular process (manual handling, working at height)

- A management system element (training, emergency procedures)

- Compliance with specific regulations (COSHH, PUWER)

2. Set Audit Criteria

What standards are you auditing against? This might include:

- Legal requirements

- Company policies and procedures

- Industry standards or codes of practice

- ISO 45001 requirements

- Previous audit findings

3. Create or Select a Checklist

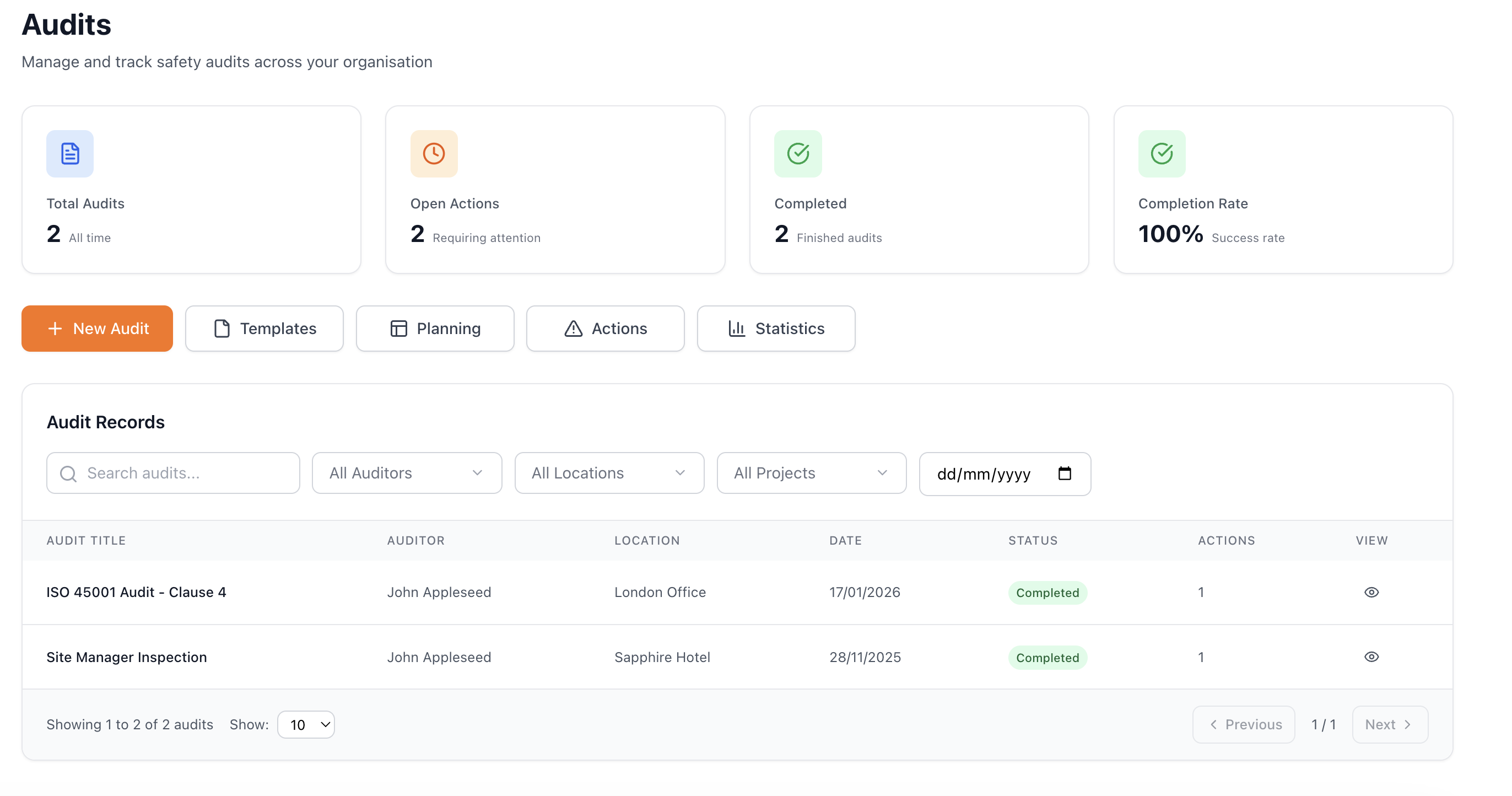

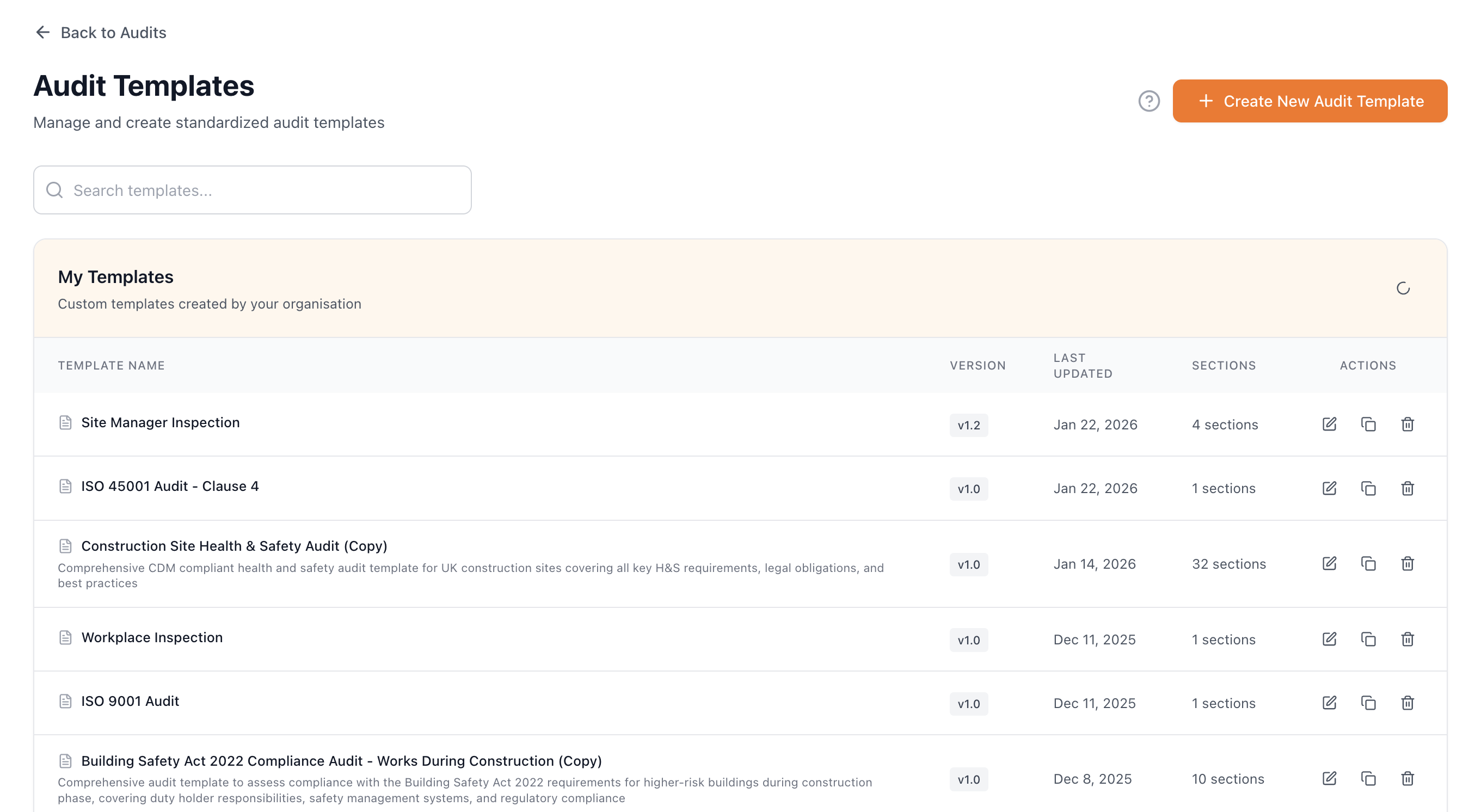

A well-designed checklist ensures consistency and helps you cover everything. Safety Mate® includes customisable audit templates you can adapt to your needs.

4. Schedule and Communicate

Decide when the audit will take place and inform relevant people. For most audits, giving advance notice is appropriate—you want to see normal operations, not a frantic last-minute cleanup.

Consider occasional unannounced audits if you suspect procedures are only followed when people know they're being watched. These can reveal the true state of safety culture.

Conducting the Audit

With your preparation complete, it's time to carry out the audit. Here's how to make it effective:

Opening Meeting

Start with a brief meeting to:

- Explain the purpose and scope of the audit

- Confirm the schedule and areas to be visited

- Identify who will accompany you

- Address any questions or concerns

Gathering Evidence

Use multiple methods to build a complete picture:

📋 Document Review

Check policies, procedures, risk assessments, training records, inspection logs, and incident reports.

👁️ Observation

Watch how work is actually done. Look at conditions, behaviours, equipment, and housekeeping.

💬 Interviews

Talk to workers, supervisors, and managers. Ask open questions about how things work in practice.

Tips for Effective Auditing

- Be objective – base findings on evidence, not assumptions

- Take photos – visual evidence is powerful for both positive and negative findings

- Note positives – audits shouldn't just be about finding faults; recognise what's working well

- Ask "why" – understand the root cause of issues, not just the symptoms

- Be approachable – workers are more likely to be honest if they don't feel threatened

Closing Meeting

At the end of the audit:

- Summarise your initial findings (no surprises in the report)

- Thank people for their time and cooperation

- Explain what happens next and when they'll receive the report

Documenting Findings

Good documentation turns observations into actionable insights. Your audit report should be clear, factual, and focused on driving improvement.

Classifying Findings

Categorise your findings to help prioritise actions:

Immediate risk to health and safety. Requires urgent action—work may need to stop until resolved.

Significant non-compliance or risk. Requires prompt corrective action within a short timeframe.

Moderate risk that should be addressed. Action required within a reasonable timeframe.

Minor issue or opportunity for improvement. Should be addressed but doesn't pose significant risk.

Writing Good Findings

Each finding should include:

- What was found – specific, factual description

- Where – location or process

- Evidence – what you saw, heard, or reviewed

- Requirement – what standard or procedure it relates to

- Risk – potential consequence if not addressed

- Recommendation – suggested corrective action

Don't just report problems. Highlighting what's working well encourages those behaviours and shows the audit is balanced and fair.

Follow-Up & Corrective Actions

An audit without follow-up is a waste of time. The real value comes from turning findings into actions and verifying they've been completed.

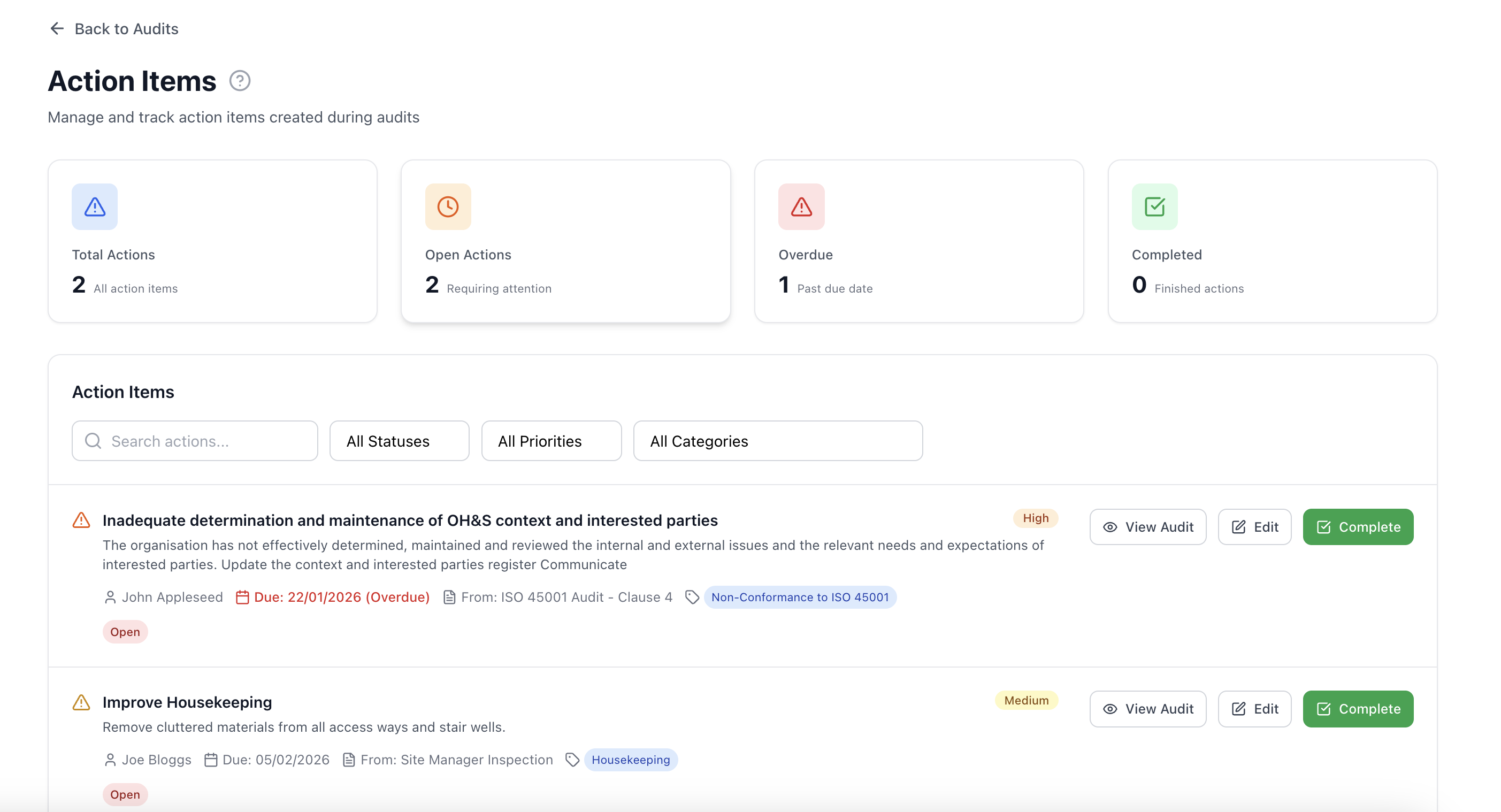

Creating Action Plans

For each finding that requires action:

- Assign a responsible person

- Set a realistic deadline

- Define what "complete" looks like

- Determine how completion will be verified

Tracking Progress

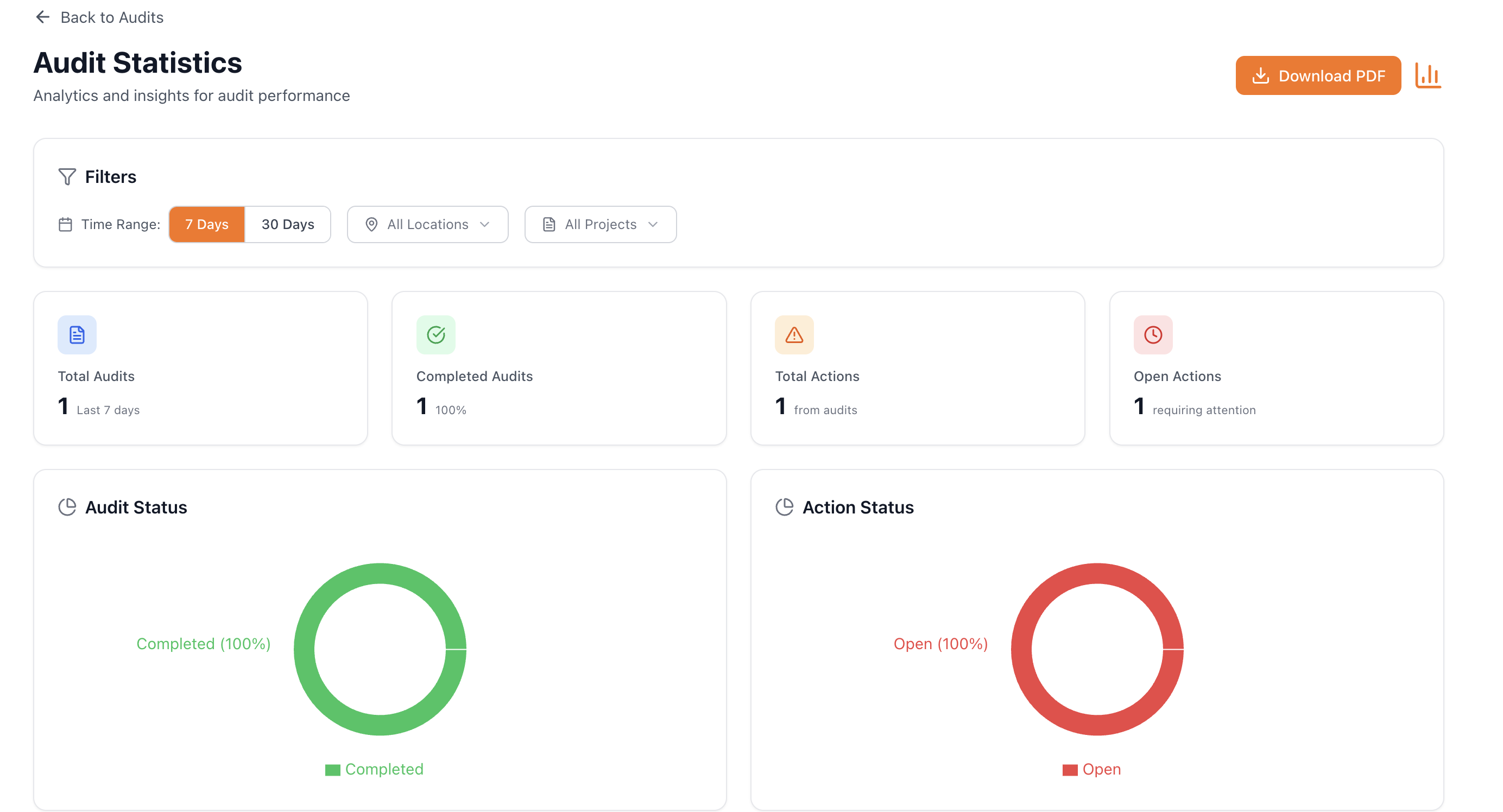

Safety Mate® automatically tracks actions from audits, sending reminders as due dates approach and providing dashboards to monitor completion rates.

Verifying Effectiveness

Closing an action isn't just about completing it—you need to verify it actually solved the problem. Include verification steps in your follow-up process.

Audit Frequency

How often should you audit? There's no one-size-fits-all answer, but here are guidelines:

| Audit Type | Suggested Frequency | Notes |

|---|---|---|

| Workplace inspections | Weekly to monthly | Quick checks of conditions and housekeeping |

| Internal system audits | Quarterly to annually | Cover all elements over a 12-month cycle |

| High-risk area audits | Monthly to quarterly | More frequent for higher-risk activities |

| External/certification audits | Annually | As required by certification bodies |

| Behavioural observations | Ongoing | Regular informal observations by supervisors |

Audit higher-risk areas more frequently. A construction site needs more attention than a low-risk office. Adjust frequency based on incident history, changes, and compliance track record.

Common Mistakes to Avoid

Treating audits as fault-finding

Audits should improve safety, not assign blame. A punitive approach makes people hide problems instead of fixing them.

No follow-up on findings

Identifying problems is pointless if nothing changes. Track actions to completion and verify effectiveness.

Inconsistent auditing

Using different criteria or approaches each time makes it impossible to track trends. Use standardised checklists.

Auditing without competence

Auditors need to understand both auditing techniques and the subject matter. Invest in training.

Only auditing when required

Don't just audit for certifications or after incidents. Regular proactive audits prevent problems before they occur.

Conclusion

Effective safety audits are about more than compliance—they're a cornerstone of a strong safety culture. When planned well, conducted professionally, and followed up diligently, audits drive continuous improvement and help prevent incidents before they happen.

Key takeaways:

- Plan thoroughly—define scope, criteria, and checklists before you start

- Gather evidence through documents, observation, and interviews

- Document findings clearly with evidence and recommendations

- Follow up on every finding and verify effectiveness

- Use software like Safety Mate® to streamline the entire process

Streamline your safety audits

Safety Mate® makes it easy to plan, conduct, and follow up on safety audits. Start your free 7-day trial today.

Start free trial